The protection of the item contained inside is the primary objective of the packaging that is printed. The product must not get damaged while in transit and must be able to resist any potential hazards it may face. Follow us.

Packaging printing steps

Concept

Packaging is a coordinated method of preparing products for transport, storage, logistics, sale, and final use. Packaging protects, conveys, informs, and sells its contents. We use it everywhere in many countries, including in personal, commercial, institutional, and industrial settings.

Design

“Packaging design” connects shape, structure, materials, colour, imagery, typography, and regulatory information with auxiliary design components to sell a product. To clarify: Your marketing strategy uses packaging.

Execution

Packaging execution systems control till identification and provide accurate information about which goods are in which boxes. Packaging execution systems scan serial numbers concurrently to connect the box and product.

Printing & design

Related Article: Packaging Design; The Most Important Part Of Marketing

Style

The name of the print style gives both the paper size and the sort of model that uses to create the area it’s print.

Size

This is a device’s biggest printable sheet. It includes: • A3/A2 paper size—These printers can print on A3 (US letter B) and A2 (US letter C) paper.

Paper or packaging type

“Packaging printing” is any printing method, such as lithographic, flexographic, gravure, or letterpress, that identifies or beautifies paper, paperboard, or cardboard objects meant to be containers, enclosures, wrappings, or boxes. Packaging printing may also include paperboard printing.

Special Effects on boxes

The unique printing method gives stamped text or pictures a professional touch. This makes foil stamping the preferred method for printing branded items. This works.

Related Article: Packaging Symbols; Protect Your Products

Prototyping

Before mass production, a package prototype needs a sample with completely printed artwork. We should make a packaging prototype before mass manufacturing. It is frequently a handcraft or made by using lightweight, specific gear.

Fulfillment: Assembly, inventory control, kitting labor and logistics

What is fulfilment? This includes printing, storing, collating, assembling, packaging, kitting, and shipping printed items. Sending printed materials. i.e., processing and delivering orders to one or more locations on a single day or throughout a month or year.

Quantities

Offset printing works best at higher quantities. It is costly for low-volume projects. Offset printing usually starts with 500 copies.

Equipment & services for packaging printing

Offset printing

First an offset print design print on a rubber cylinder and then transfer to the product, such as a glass bottle or candle jar. Offset printing is widespread. This method prints large quantities at little cost and produces high-quality, consistent output.

Die-cutting and embossing

Using an embossing machine to raise the print above the box A metal die, like a cutting die, etches the appropriate area into the material.

Folding carton gluing

What’s “folding and gluing”? Automated folding and gluing may turn flat die-cut material into folding cartons, promotional material, or envelopes.

Inline flexo printing

Inline flexo converts thinner, lighter, and recyclable materials. Packing and delivering substrates quickly. Water-based inks provide excellent colour.

Inspection systems

What exactly is a system of inspection? A number of different items inspected in real-time using an inspection system, which is an automated, cost-effective method.

Hot foil stamping

“Hot stamping” involves pressing a metallic pattern and foil onto a material using hot dies. This material might be glossy, holographic, matte, or any colour and texture.

Services and consumables

This word refers to using printing supplies. Laser and inkjet desktop printer cartridges are classic examples.

Best printing methods for packaging

Lithography or Offset Printing

Offset printing, also known as offset lithography, transfers pictures from metal plates to rubber blankets or rollers and ultimately to print medium for large manufacturing. Print media—usually paper—does not touch metal plates.

History

Related Article: The History of Packaging, The Evolution Of Packaging Design

In 3000 B.C., proto-Elamite and Sumerian civilizations used cylinder seals to authenticate clay tablet writings. Printing began here. Early printing included block seals, hammered coins, ceramic imprints, and cloth printing.

The Offset Printing process

Offset web press

Web offset presses slice large rolls of paper during or after printing. These machines can print tens of thousands of feet of paper each hour without reloading precut sheets. Web offset presses are ideal for mass-producing catalogues and magazines.

Offset Sheetfed Press

Sheetfed offset printing machines may print on individual sheets of paper, cardboard, or other materials. Sheetfed offset printing presses employ different feeders to feed these sheets into the machine. In long and short manufacturing runs, folding cartons are used to package cereal, cosmetics, and other items.

Finishing Presses

After printing, value-added operations are called finishing. Most finishing techniques are done offline after the printed product comes off the press; others are done inline.

Prepress

Prepress is the process of cutting and printing your company’s packaging. Die lines and proofs are used to create a digital duplicate of the box’s shape and aesthetic.

Offset Inks

In traditional offset printing, aluminum plates deposit ink onto a rubber blanket.” The image is rolled onto the printing surface. Because ink is not directly applied to the paper, this printing process is called offset.

Substrates

Printing substrates are used for printing. Paper, cardboard, foil, and metal sheets are printing substrates. The more general term “substrate” includes embossed materials as well as printed ones.

Prepress e CTP in offset printing

CTP technology ensures offset printing’s highest quality. CTP eliminates harsh chemicals and the intermediate film processing step. Prepress production saves and retrieves print data digitally.

Advantages and disadvantages of offset printing

Advantage: It’s ideal for consistent commercial printing operations. Turnover and setup are drawbacks. Editing and proofreading take time and money.

Flexographic Printing

A positive mirrored master of the picture is generated as a 3D relief in rubber or polymer for flexographic printing. Flexographic plates may be either analogue or digital. Rubber or polymer plate images are lifted over non-image parts.

Digital Printing

Digital printing directly prints pictures onto different media substrates. Offset printing requires plates. Digital files may be printed directly on paper, picture paper, canvas, fabric, synthetics, cardboard, and other substrates. PDFs and desktop publishing files

Digital Printing for Packaging: An Introductory Guide

This process applies ink to product packaging. Most digital printers use toner and liquid inks instead of solid inks that soak into the medium.

What Is Digital Printing for Packaging?

Product packaging is printed digitally. Most digital printers use liquid inks and non-soaking toner. UV curing or laser heating seals product packaging ink. Litho lamination and flex ology transfer ink to packaging using print plates and cylinders. Inks partially absorb substrates. No print plate is required for short-run package printing using digital printing.

Is Digital Printing Effective for Packaging?

Digitally printed cartons can accurately reproduce gradients and design elements. Digital printing can print the whole CMYK spectrum on a variety of paper substrates, but folding cartons are perfect. Traditional printing may be preferable for complicated, rough materials like corrugated cardboard or chipboard.

Benefits of Digital Printing for Packaging

Digital boxes are great. It is becoming increasingly popular for product packaging due to its quality and versatility. Digital printing for packaging may suit your printing and packaging demands for these reasons.

Speed

Digitally printing product packaging speeds the design-to-product process. Digital printing skips the time-consuming print plate creation procedure. Digitally printed cartons may be made on demand without waiting.

Cost

Print plates and conventional printing take time and effort. This extra work takes longer and costs more to make a product.

Rapid Prototyping

Digital printing makes product packaging prototypes quickly and cost-effectively. Digital printing lets you experiment, so you can be sure your product packaging will appeal to your target audience.

Customer Responsive Designs

Top brands understand relationship marketing. Consumer-facing businesses succeed. Modern clients want personalized products and packaging. Digital printing suits short, specific product package runs. Holiday, promotion, and customer demographic boxes are easy to develop digitally. Digital printing lets package designers quickly and inexpensively develop new product packaging designs. Independent printing encourages creativity and innovation.

Eliminate Minimum Order Thresholds

Digital printing lets you make small quantities of product packaging on demand with no setup. Digital printing directly prints product package designs on boards, simplifying manufacturing runs. Most conventional printers need a minimum order to justify setting up their equipment.

Supports Just-in-Time Inventory

Printing small quantities of product packaging quickly and cheaply helps firms streamline operations. Companies may better employ their operational resources and meet consumers’ shifting needs by keeping less inventory.

Less Waste

Digital packaging printers avoid overprinting. Traditional packaging printing methods waste a lot. These procedures favour bigger batches that typically leave product packaging unused. Product packaging that changes branding or specs is either recycled or thrown away. Digital printers excel at producing modest product packaging runs to suit demand. Reducing product packaging inventory saves money and operational resources.

Environmentally Friendly

Digitally produced boxes save money and the environment. This technology generates fewer landfill-bound ink cartridges and less air pollution than traditional printing.

Related Article: Sustainable Packaging; A Good Strategy in Branding

Is Digital Printing for Packaging Right for You?

Digital printing on cartons offers several advantages for company owners seeking innovative, cost-effective methods to boost product attractiveness. This adaptable alternative to standard product packaging may not be ideal for every purpose. We have years of product packaging and industry knowledge to realize your idea. Contact the Customer Care Team via phone or Live Chat with any queries concerning digital printing for product packaging! We care about your company.

Rotogravure Printing

Rotogravure is an intaglio printing method that involves engraving the image onto an image carrier. Gravure printing, like offset and flexography, employs a rotary printing press to etch the image onto a cylinder.

Silkscreen Printing

Serigraphy, or silkscreen printing, is a complicated stenciling procedure. This method prints by rubbing, rolling, or spraying paint or ink through a pattern cut from paper or a similar thin, durable material.

A Comparison of the Different Types of Printing for Packaging

You’ll need to compare your product’s packaging printing methods throughout the packaging redesign. Printing processes fit different end-use applications. This guide will help you choose the right printing options for your project.

Offset Lithography

Offset lithography is used to print folding cartons, corrugated packaging, and large labels for packaging and retail displays. The photograph is lithographed onto an aluminium plate and then transferred to a rubber covering for processing. After that, the picture is printed onto a substrate and coated or varnished, depending on the desired aesthetic and degree of protection.

Flexography

Flexographic printing has been used for decades for high-volume labels and flexible packaging, including food and beverages. A rubber relief plate wraps around a cylinder to print the design. An anilox roller, a metal or ceramic cylinder with small “cells,” transfers ink to the plate, which touches the substrate quickly and cheaply. Flexography advocates say it can now equal offset because to improved quality and automation.

Digital printing

Product packaging is increasingly printed digitally. Digital printing is relatively young compared to flexo, offset, and gravure printing, but it is growing fast. Due to its higher quality, faster print rates, and lower operational costs, inkjet printing is gaining popularity.

Gravure

Gravure prints on metal cylinders The printing machine progressively applies ink to each cylinder, creating a high-quality image. It is recommended for elaborate package designs and flexible food packaging.

Screen printing

As the name suggests, a woven silkscreen generates your design. The fabric’s uncoated parts are coated with ink. Since printing surfaces don’t need to be flat, this inking method may adhere to paper, fabric, glass, and metal.

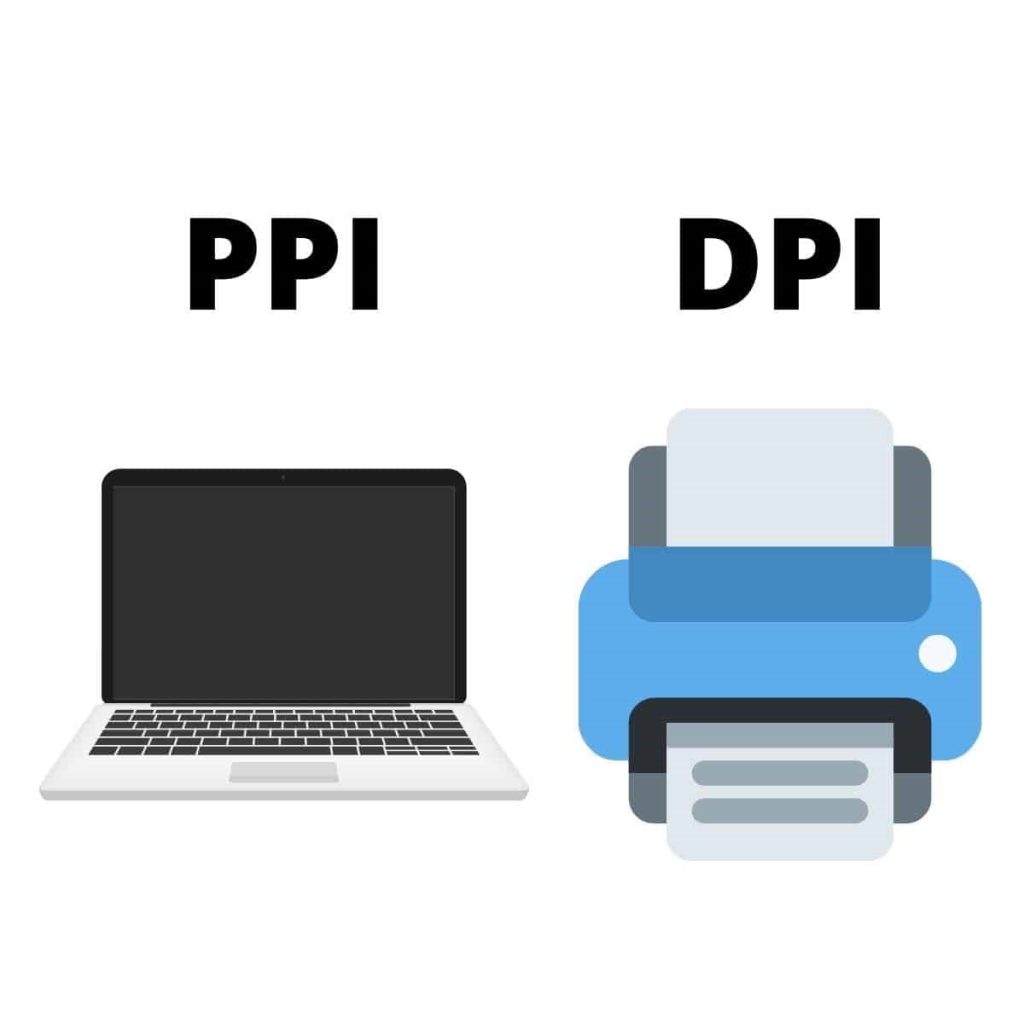

What is meant by image resolution?

PPI, or pixels per inch, describes picture resolution. Resolution enhances PPI. This increases the amount of information in each pixel, producing a clearer, higher-quality image.

PPI or DPI: what are the differences?

PPI—pixels per inch—is used to describe picture resolution. Resolution enhances PPI. This increases the amount of information in each pixel, producing a clearer, higher-quality image.

What is the resolution of an image for printing?

300 PPI printing is usually optimal. A 300-pixel-per-inch picture will seem clean and distinct. This resolution is equivalent to 300 DPI printing. These are high-res images.

How to know an image resolution?

Right-click on the photo and choose “Properties.” A new window will display the image’s details. Click “Details” in the menu bar to view the image’s dimensions.

printing with bio-based materials

Three-dimensional (3D) bio printing uses cells, growth factors, and biomaterials to create biomedical components that mimic natural tissue features.

water-based technology for flexible packaging inks

Dispersion and disappointment Pigment dispersion and a letdown or extender make up water-based ink. Resins disperse pigment efficiently and effectively, resulting in uniform ink colour.

Our water-based emulsions for use in industrial ink applications

Packaging supplies that needs printing

Stand up pouches

Want to seal your edibles easily and securely? Print airtight pouches. Protecting powdered, dry, and liquid items extends their shelf life. Each bag stands tall, so your item stands out. Its robust yet lightweight material makes big orders easy to store and carry.

Flat pouches

Packaging may affect sales more than you think. It reaches your target audience, shows your brand values, and provides product information. Flat pouches can do this and more. Flat pouches are quite versatile. Granola, cereal, organics, and vitamins are nicely packaged. Flat pouches protect against moisture and oxygen. This packaging ensures freshness and security throughout shipping, storage, and display.

Poly mailer

The greatest approach to wowing customers Custom-printed mailer boxes for great unpacking Customers may have a unique unpacking experience in your bespoke mailer boxes when you deliver e-commerce products or subscription boxes. Print wine, beverage, garment, shoe, and gadget boxes.

Labels (roll labels)

Custom label printing lets you add your business name, logo, or message to any surface. To match your brand, choose the right size, shape, and finish. Design in over 20 sizes and customize using our online tool.

Header card

Make eye-catching header cards. Bag toppers are great for sealing items and packing party favours like cookies or handcrafted accessories. Put your things in a plastic bag, fold the header card, and staple it on top.

Gummed paper tape

Poly packing tape

Customize shipping tape to seal boxes. Customers can easily recognize their expected parcel arrival with your logo and business name repeated. Every company purchase builds a brand association.

Packaging sleeves

Want to mark hundreds of boxes quickly and well? Create wraparound packing sleeves. It saves time and effort on box design. Showcase your brand and product details. The strong 100-lb. paper sleeves enhance your company’s professional appearance.

Retail entrepreneurs may brand their hangtags. A unique price tag helps distinguish your item. Choose from our many sizes, shapes, and quality paper materials to stand out in today’s competitive market.

Wrapping paper

Custom wrapping paper is appealing. These are bought and used to surprise loved ones. Wrapping paper may be printed on both sides and comes in several sizes.

Custom tissue paper

Custom tissue paper is a great packaging option for small companies, but it provides much more! Tissue paper may be used as packing filler or present wrapping. Line a box with it for an elegant look.

Gift bags

Our printed self-seal paper gift bags are the top option for cosmetics firms, jewellery merchants, perfume boutiques, gourmet food stores, and high-end sports stores searching for beautiful packaging for their high-quality items. This best-selling line has two styles and automated and handcrafted solutions for any budget.

Paper bags

Custom greaseproof paper is an excellent method to raise awareness of your business and provide space for your logo to stand out, whether you use it to line, wrap, or showcase anything.

Plastic bags

Advertising using printed carrying bags is ideal. Print your business logo or design on our high-quality carriers to stand out and let your consumers do your promotion. Only Polybags can give you a fast, real-time quotation on your printed carrier bag order, 24 hours a day, seven days a week. Quote in less than 60 seconds!

Euro totes (matte, gloss and frosted bags)

Euro totes have reinforced bottoms and rope handles. It use heavyweight paper for elegance and durability. They are eco-friendly, reusable shopping bags.

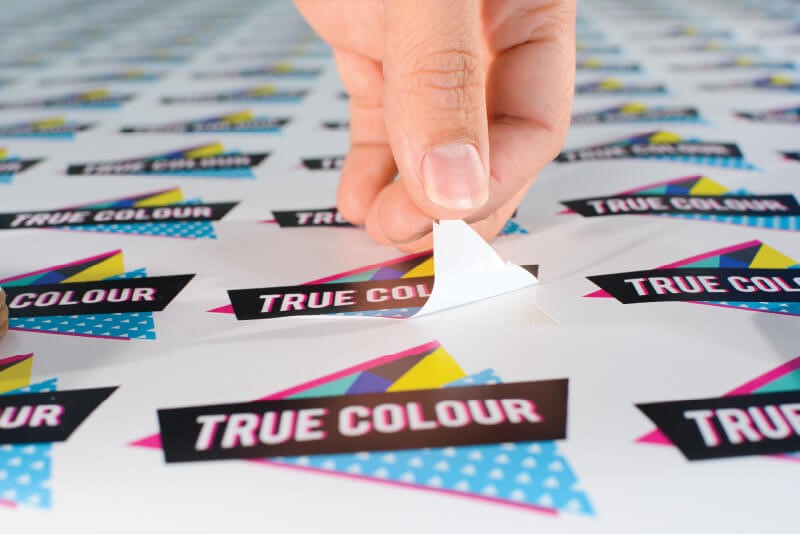

Stickers

Stickers enhance seasonal packaging and product launches. Redesign your events, campaigns, and freebies, like bumper stickers. We print your graphics on weatherproof materials. Print on white sticker paper for retail displays.

Address labels

Address label printing is used for mail and courier deliveries. Packages and envelopes use them most. They display sender and recipient addresses.

Shipping and mailing label

Shipping labels define and identify a package’s contents. These labels carry important information such as addresses, names, weight, and tracking barcodes.

Child resistant stand up pouches

Child-resistant packaging prevents youngsters from opening and consuming dangerous items. Child-resistant zippers allow pouch reseal ability in these bags.

Child resistant flat pouches

Child-resistant (CR) containers prevent youngsters from opening and consuming dangerous items. Child-resistant press-to-close zippers allow pouch reseal ability.

Custom bubble mailers

Your cargo will arrive safely since the film is glued to a cushioning substance. These reusable, 100% recycled plastic envelopes are a perfect alternative to carton packing.

Ribbons and bows

Bows and ribbons may embellish intimates, jewellery, hair accessories, clothes, and gift wrapping. Ribbons and bows may be decorative or utilitarian in packing.

Backing cards

Backing cards support products. They’re ideal for branding. Backing cards make your products seem great and attract customers.

Wrapping paper

Creative wrapping paper shows your generosity via pattern, colour, surface, and more. Customize Gift wrapping dominates the gift business. For birthdays, anniversaries, retirements, and holidays, wrapping is a custom. Gift wrap adds character. So wrapping paper design is art. Present wrap paper may transform an ordinary present.

Bottle neckers

These little hang tags use on bottles of wine, spirits, and motor oil. These little POP message billboards influence what shoppers purchase off the shelf.

Belly band

Belly Band Packaging? Custom packaging sleeves called belly bands wrap a product. Belly bands may protect and mark goods as packaging.

Printing packaging refers to the process of creating customized packaging materials, such as boxes, bags, or labels, by using specialized printing techniques. This type of packaging serves both functional and aesthetic purposes, as it protects products during shipping and also serves as a marketing tool to attract consumers. Printing packaging can be done on a variety of materials, including paper, cardboard, plastic, and metal. The process involves designing the packaging, selecting the appropriate printing method, and producing the final product. The resulting packaging can be used for a wide range of products, from food and beverages to cosmetics and electronics.