The material used to make a bottle determines its density. Plastic bottles store water, soft drinks, motor oil, cooking oil, medicine, shampoo, milk, and ink. Liquid transfer is also frequent. From small bottles to huge carboys Consumer blow-molded containers usually feature handles or are easy to hold. Follow us.

The history of plastic bottle

Before high-density polyethylene was invented in the early 1950s, plastic bottles were expensive. Plastic bottles are cheaper and lighter than glass bottles, making them more convenient for consumers and manufacturers.

Production process

Manufacturing requires labor, money, and land. Most manufacturing methods aim to produce goods quickly and efficiently without compromising quality. Manufacturing objectives, output, and technological equipment or software determine a company’s production technique.

Petrochemical resins

Polymerizing olefins, diol fins, and aromatic vinyl compounds yields petroleum resins and synthetic hydrocarbon resins. Cracking natural gas liquids, gas oil, or petroleum naphtha produces these unsaturated monomers. Synthetic hydrocarbon resins are petroleum resins.

High density polyethylene (HDPE)

HDPE is a petroleum-based thermoplastic polymer. This plastic is used in bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and pipes. HDPE plastic offers great impact resistance, melting temperature, and tensile strength. This makes HDPE plastic ideal for many applications.

Related Article: Glass Bottle Packaging

Fluorine-treated HDPE

Fluorinating polyolefin modifies polymers (plastics) with fluorine to create a high-performance barrier that reduces permeation through container walls and protects against environmental weathering and degradation. To fluorinate polyolefin, this is done.

Low-density polyethylene (LDPE)

LDPE is used in the production of a wide variety of containers, including dispensing and squeeze bottles, tubing, plastic sections of computer components, molded laboratory equipment, and a variety of caps and closures.

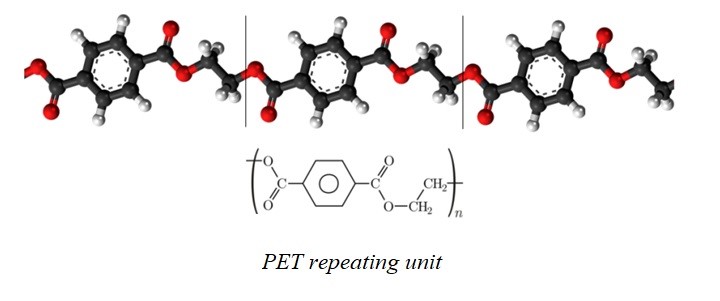

Polyethylene terephthalate (PET, PETE)/Polyester

PET, or PETE, a linear, semi-crystalline thermoplastic polymer, has several uses. Polyesters make it. These resins are noted for their unique combination of qualities.

Polycarbonate (PC)

Polycarbonate (PC) plastics are transparent, amorphous thermoplastics. They are sold in a variety of colours, some of which are translucent, but the raw material lets light flow through like glass.

Polypropylene (PP)

PP, a rigid, semi-crystalline thermoplastic, is known for its durability. Its transparency and opaqueness provide a wide range of colours. It may be used to reduce weight because of its decreased density.

Polystyrene (PS)

PS foams or stiffens. Polystyrene is odorless, colourless, stiff, and has a mild melting point. Protective packaging, food service packaging, bottles, and food containers are examples.

Polyvinyl chloride (PVC)

Shampoos, oils, and other long-term storage items may be stored in PVC bottles. New PVC plastic containers are ideal for hot-fill applications since they can withstand 140°F. Clear PVC bottles are streaky.

Post-consumer resin (PCR)

PCR resin is a polymer made from recycled plastic bottles and other packaging. It offers a greener alternative to virgin plastic resin for making packaging films, containers, sheets, and other products.

K-Resin (SBC)

K-Resin® SBC may be blow-molded into small pill bottles and medical drainage units for towering display bottles. These items are versatile. They may also be injection-blasted into high-impact glass-like bottles.

Other materials

Bioplastic

Bioplastic Bottles Bioplastics, unlike ordinary plastics, are made from biological sources and are biodegradable. “Bio based” just describes the substance’s origin, not its disintegration.

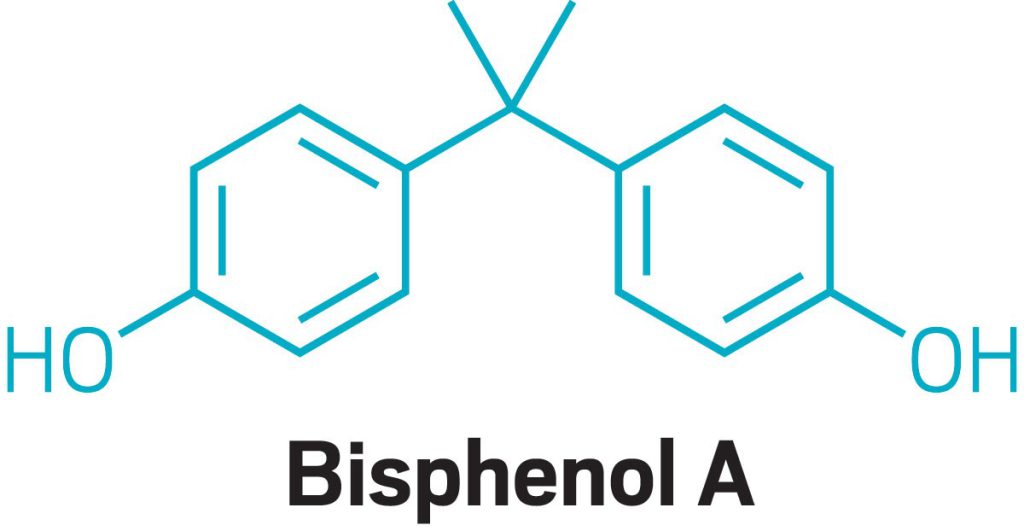

Bisphenol A (BPA)

Bisphenol A (BPA), a widely produced chemical, is used to make polycarbonate plastics. Shatterproof glass, eyeglasses, water bottles, and epoxy resins that cover metal food cans, bottle caps, and water supply pipes employ it. A few items use it.

Concerns

Plastic packaging has demons. Plastic’s mass production, durability, and flexibility made it a breakthrough material, but its environmental implications have become more apparent. Plastic packaging decomposes slowly. This material garbage pollutes land and water. Plastic pollutes and kills animals.

Labelling

The bottle label tells the consumer where and who made the product, what components it contains, and any other relevant information. Bottle branding may distinguish products and attract buyers.

Resin identification code

Some hard plastic containers include resin identifying codes. There may be codes. They were founded in the 1980s to categories plastic into distinct categories to standardize plastic manufacturing and recycling.

The advantages of plastic bottle

One-time plastic water bottles are popular. They are affordable, lightweight, and available in many shapes, sizes, and colours. They won’t shatter if dropped, either. Plastic water bottles may also be recycled several times.

Bottle water regulation and FDA

The FDA defines bottled water as water intended for human consumption, sealed in bottles or other containers, and free of additives except for approved antibacterial agents. Identification Standard Section 165.110(a) defines this.

Plastic and human health

Earth’s parched. Despite adequate water supplies, many Americans and foreigners purchase water in plastic bottles. Disposable water bottles are used regularly but should be preserved for situations like natural catastrophes. Yes, preserve some for natural disasters. Disposable water bottles are costly yet handy. BPA-laden disposable water bottles hurt the environment.

PET bottle recycling

Contrary to common assumptions, PET is a thermoplastic polymer resin without polyethylene. Since it melts at around 245 degrees Celsius, it may be made and recycled in many ways. PET polymerization requires terephthalic acid and ethylene glycol. PET uses non-food bottles.

Plastic pollution

A one-liter throwaway PET bottle requires 162g of oil and seven liters of water. This releases 100g of greenhouse gas CO2. Even recycled single-use plastic bottles pollute.

Related Article: Sustainable Packaging; A Good Strategy in Branding

Effects of plastic on oceans and seabirds

Plastic reduces stomach capacity, causing starvation. Plastic-filled dead seabirds are prevalent. Marine birds eat plastic waste. Albatrosses may eat fish eggs on floating trash.

Effects on freshwater ecosystems

Another contributor to environmental damage are the plastic bottles that are used to package bottled water. These bottles are composed of a kind of plastic known as PVC, which contains hazardous pollutants that may be released into the environment and contribute to pollution as well as a variety of health issues.

End of life PET bottles

PET bottles are collected from the general public, where they are then processed before being sent to a recycling factory together with other recyclable materials. The recycling business currently has unused recycling capacity, so collection is the most important aspect of the process.

Re-use of PET bottles

The risk that chemicals will seep out of the containers’ myriad of minute fissures and divots as a result of repeated reuse of plastic bottles—which get dinged up as a result of regular wear and tear while being washed—increases with the number of times that the bottles are recycled.

Recycling symbols on plastics

Almost all plastic goods include the universal recycling sign, which is a triangle with three arrows pointing in a circle around its center. The kind of plastic may be determined by the number within the triangle. There are six categories of plastic that are most often used, and the seventh category is for miscellaneous plastics.

Colored PET

White and coloured (opaque) PET plastic bottles are far more difficult to recycle than clear PET plastic bottles (like those used for fizzy drinks or water), which are recycled at a much higher rate.

Benefits of using bottles for product packaging

Easy to Adapt

Bottles may be altered in size, shape, and colour. Your company will mark your bottle by printing a label or adorning it directly. It may be decorated directly or labelled. Choose the material, size, finish, colour, and closure to create the ideal product packaging.

Plenty of Fillers

Bottles can hold anything, whether you offer luxury cosmetics or soda. Bottles store and carry gels, lubricants, and oils in medicinal, industrial, and other industries. Discover how our bottle filling service may benefit your goods, regardless of industry.

Practical

Simple bottling. Easy product access will please your consumers. Change your bottle closure to decrease waste, deterioration, and contamination. Customers may rest assured knowing their product is secure and accessible in its bottle packaging. No crumpled tubes or jars expose the chemical, making bottles handy. You own every drop.

Refillable

Give customers a gift that keeps on giving. Why not provide a discount when customers refill their bottles, most of which are glass? You will satisfy clients and provide them with environmental peace of mind. Your eco-friendly approach will please consumers and reduce waste.

Protect Products

Bottles are hygienic because the product is not exposed to air or other impurities until it is consumed. Unlike a screw-top pot or defective cap, a bottle protects the product. This extends product life and minimizes waste. Make a sanitary product promise to your customer, then provide a product with a lower chance of going bad than your competitors.

Durable

Bottles reduce contamination and wear and tear. Plastic and glass bottles are durable. Bottles are more durable than cheap plastic pots and aluminum cans, which break easily. High-quality, robust materials and careful transportation may reduce the danger of packaging damage or breakage.

Cost-Effective

Manufacturing, transporting, and recycling plastic bottles is cheap. Plastic bottles are lightweight and can be shipped and moved cheaply. This material requires less energy to create since it melts at a lower temperature. Plastic production is energy-efficient.

Easy to Recycle

Most plastic and glass bottles are recyclable locally. Plastic is hated and misunderstood. In an eco-conscious society, recyclable packaging is vital for corporate sustainability. Buyers will choose your products over those of competitors if they can recycle the packaging. Recycling pays.

Fillcon

Fillcon, based in the South West, provides the best packaging solutions for gel, liquid, and cream goods in various industries while maintaining environmental standards. We can fill a variety of bottles, sachets, and tubes using liquid-filling technology.

alternative to plastic water bottles

Glass bottles

Glass is non-toxic, inexpensive, and can be recycled forever. Reusing glass jars for food storage is free. Glass packaging allows this. Jam, honey, pickles, nut butter, and other jars may help you reduce waste. Bulk bin purchases may use these jars. They may also be used to store leftovers, drinks, and homemade gifts.

Metal bottles

A food-grade stainless steel water bottle is the best alternative to plastic bottles since it does not leak chemicals, even when filled with hot liquids. It replaces plastic bottles best.

Paper cups

Paper packets sold various products in the past. This material is better than plastic, but its fibers shorten with use, limiting its recycling. Your backyard compost bin can accept most paper, even glossy paper.

Chemical contamination in plastic bottled water

The European Union and China have banned BPA-containing plastic because it is dangerous. BPA exposure has been linked to fertility, brain development, cancer, and heart issues.

Environmental impact of plastic bottles

Plastic pollution is a major environmental concern nowadays. 400 billion plastic water bottles were consumed worldwide in 2016. Nine percent of plastic is recycled, while ninety-one percent goes to landfills or the ocean. Only the US consumes 50 billion plastic bottles annually, or 100 million water bottles every day.

PET plastic facts

PET bottles help soft drink companies and consumers. 70% of soft drinks—carbonated, still, dilatable, fruit juices, and bottled water—are in PET plastic bottles. 30% of soft drinks come in glass, metal, and cartons. Plastic bottles are misunderstood despite PET plastic’s virtues. This tutorial covers various issues.

Plastic bottle by shape

Cylinder bottles

We sell high-quality PET, PVC, PS, PP, LDPE, and HDPE plastic cylinder bottles. Depending on the material, cylindrical plastic bottles are natural, white, black, amber, green, blue, or clear. Plastic cylinder bottles with flip-top pour spouts, sprayers, pumps, droppers, and more are available to suit any product line. Click on the plastic cylinder bottle picture to learn more and buy.

Foam pump bottles

A machine that has a spring and is designed to help in the dispensing of a predetermined volume of liquid is known as a foam pump. The contents of these bottles are often soaps or cleaning solutions, making it possible to use those items without sacrificing hygiene standards.

Spice bottles

Kitchens benefit from empty spice bottles. Label stickers. Fill them with things you use often, such cornmeal to shake in bread pans, flour for rolling pins, or homemade beef dry rub. They’re ideal for normal and powdered sugar.

Honey bottles

A complete beehive with a glass bottle produces a honey bottle. Honey bottles make honey blocks and sugar and eliminate toxins when drunk.

Spray bottle

Spray bottles are great for spraying detergents, disinfectants, and viscous substances into hard-to-reach regions. They usually have chemical-resistant triggers or pump sprayers.

Industrial round bottles

Industrial round bottles are used in many industries. Chemical, food, automotive, janitorial, and home products utilize these bottles for any liquid. • HDPE. 64 oz., 128 oz., and 5 liters.

Modern bottles with a raised edge around the base and shoulder

Boston round bottles with squeezable sides and rounded base and shoulder

Dairy around bottles

Glass milk bottles hold milk. They help milkmen deliver fresh milk to clients’ doorsteps and are usually reusable. After finishing the milk, customers must rinse their bottles and leave them at their doorway for collection. Customers may return washed bottles to partnered retail outlets. Bottle sizes vary by country, but pint, quart, and liter are prevalent.

Dairy jug bottles

Plastic milk containers store, transport, and distribute milk. Jugs, or plastic bottles, have replaced glass bottles as the principal household drinking vessel. Lightweight plastic milk bottles can only be used once, whereas glass milk bottles have a long history of reuse.

Diamond bottles with squeezable sides

a bottle made of flexible plastic that, when pressed, releases its contents into a separate container.

Twin neck bottle (usually used for medical, pet, agricultural or animal products

Twin-neck bottles have a purpose. These bottles are often used to store fuel additives, fertilizers, and other diluted products. These bottles are usually made of chemical-resistant heavy-duty polyethylene. Items come in all shapes and sizes.

F-style bottles (usually used for industrial or chemical uses, such as gas, anti-freeze or oil)

Heavy-duty Plastic F-Style Bottles include a handle near the opening to make handling and pouring simpler. F-style bottles are rectangular, making shipping and storage easier. Industrial solvents like cleaning and gardening chemicals use this container.

Packer bottles (usually used for vitamins or other pharmaceutical purposes)

Bottles used for packing pills are often referred to as packer bottles, pill packers, or just packers. Pills, drugs, herbs, capsules, gel caps, and vitamins may all be stored in these bottles thanks to their specific design.

Cosmo bottles with squeezable sides and with or without dispensing lids (usually used for cosmetics)

The PET Cosmo round plastic bottles’ rounded shoulders provide refinement to any personal care line. BPA-free, food-grade plastic is used to make these “bullet bottles,” which are transparent and shiny.

Custom bottles packaging

“Custom packaging” is tailored to your business and product. It matches the brand’s product to increase consumer satisfaction and brand recognition. Most bespoke packages include: Custom logo. Correct package dimensions

Special plastic bottle types

Collapsible bottle

Like other reusable water bottles, a collapsible bottle may be filled at home or on the go, but unlike stainless steel, glass, or hard plastic bottles, it shrinks when not in use, saving space.

Carbonated drinks bottle

A bottle for carbonated beverages that is insulated with a vacuum and permits you to carry fizzy beverages anywhere and at any time is referred to as a vacuum-insulated bottle.

Squeeze bottle

Squeeze bottles discharge liquid when the user squeezes them. Plastic squeeze bottles are common. A robust hollow body compresses and expels liquids through a nozzle using manual pressure. Device’s main feature.

Wash bottle

In chemical and biological laboratories, wash bottles are squeeze bottles with long, bent beaks. Most are made of a relatively stiff plastic that yields under pressure. Squeezing the bottle applies the same pressure to the liquid within.

Designing plastic bottles for maximum recyclability

It is possible to prevent things from ever being considered “waste” by designing them with the potential to be recycled, which opens the door to closed-loop material recovery.

Style plastic bottle design

When we talk about bottle designs, we’re referring to the form and design of bottles that either contain a trademark or are considered to be trade dress.

Classic and elegant design

adjective. Elegant means graceful and attractive. Classic furniture has inlay, carved or turned legs, and intricate, floral- or fauna-inspired ornamentation. Popular fabrics feature texture, subtle patterns, and stripes with block colours.

Sophisticated but understated design

Understated elegance is simple, refined, and classy. It’s called “elegant simplicity.” It has linear lines, muted colours, and little decoration. Quality, design, and function are prioritized above quantity. It is a timeless design concept associated with luxury and refined taste.

Personalized and unique design

a procedure that modifies a system’s features, such as its interface, information content, or distinguishing characteristics, in order to boost the personal relevance of the system to an individual.

How to design a plastic bottle?

Define bottle requirements

After being sorted, cleaned, and shredded into flakes, the used plastic bottles are processed into recycled PET resin, which may then be used to make new bottles for beverages and other types of food-safe packaging.

Define manufacturing and filling requirements

To ensure product and consumer safety, cleanliness, and acceptance, packing volume and weight must be kept low. To ensure product and consumer safety, cleanliness, and acceptance, packing volume and weight must be kept low.

Select materials for the prototype

Plastics are flexible materials that may provide possibilities for the easy packaging of food and beverages. Because they do not leak dangerous compounds, polyethylene (PE), polypropylene (PP), and polyethylene terephthalate (PET) are the three forms of plastic that are ideal for use on perishable goods.

Rough drawings for the plastic bottles design

Drawing part for the plastic bottle

The neck of the container is above the shoulder and below the finish. The bottle’s finish joins the neck when its cross-section narrows. Finish: The top piece of the container, above the neck, accepts a specified-size closure.

Related Article: Paper Packaging; It’s Pros & Cons

Model and rapid prototyping

“Rapid prototyping” is the three-dimensional CAD fabrication of a physical object, model, or assembly. 3D printing, or additive manufacturing, is usually used to finish a component, model, or assembly.

Mold drawing

Moulding plastics may be done in a variety of ways, one of which is injection moulding. This technique is used in the production of a wide variety of shipping containers, packaging for industries, cosmetic items, and home chemicals, as well as a variety of closures, such as those used for PET bottles or fragrances.

Unit cavity of extrusion blow molding

A cavity mould makes the preforms outside, and a core rod clamped around it creates its inside. A thick polymer tube attached to the preform—a bottle or jar neck—will create the product’s body.

Unit cavity sampling and testing

Finalize drawings of actual bottle design

A package’s objective is to sell a consumer product by expressing its personality or function. To achieve these goals. A typical grocery store offers tens of thousands of goods.

Actual production run of the bottle mold

Production mold sampling and testing

Extruders melt little plastic resin pellets. They are then injected into a steel mould to make plastic tubes. Plastic bottles begin as preforms. Air injection gives this heated preform the shape of the moulded bottle.

Production startup for the user

When we talk about “production start-up,” what we really mean is the moment when a first shipment of a Generic Product Family is made in accordance with the initial Weekly Start Schedule for that Generic Product Family.

Bottle packaging refers to the use of containers made of glass, plastic, or metal to store and transport various liquids and beverages such as water, soda, juice, and alcohol. The packaging is designed to protect the contents from external factors such as sunlight, air, and moisture, while also providing convenience for consumers to use and carry the product. Bottle packaging comes in various shapes, sizes, and materials, and is widely used in industries such as food and beverage, pharmaceuticals, and cosmetics.